Pictures

Features

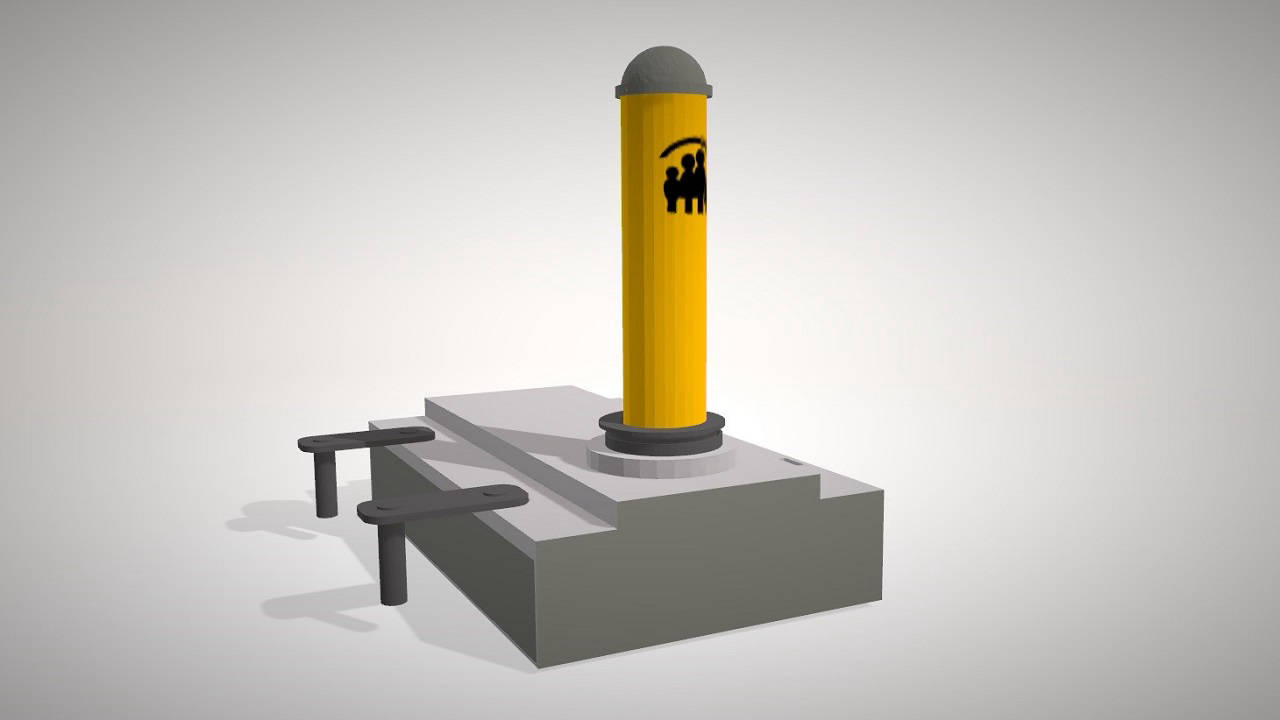

The removable security bollards allow temporary access to areas requiring protection. By the loose design maintenance and installation work can be carried out without any problems.

Below are the features of the system in detail:

- Crossing protection for trucks of 7.2 t total weight with a speed of up to 80 km/h to secure areas and access roads against terrorist attacks

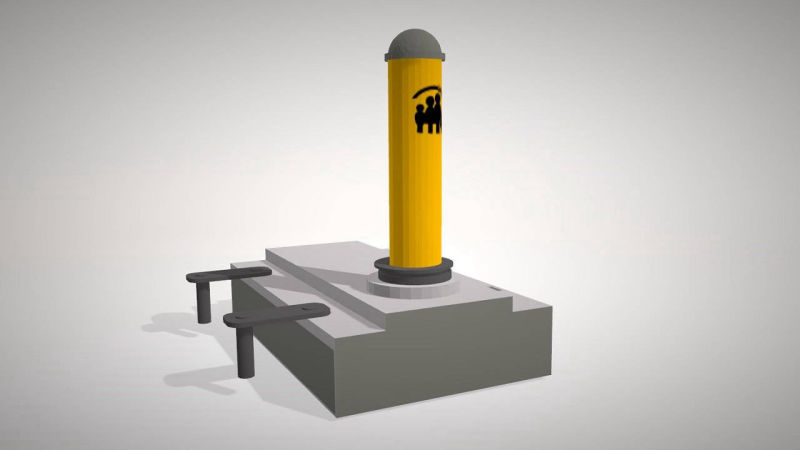

- The bollard height is 90 cm above floor level (without bollard cap). Diameter of the steel bollard is 250 mm

- Removable steel bollards in a coverable steel sleeve allow temporary access to secured objects in case of repair and maintenance

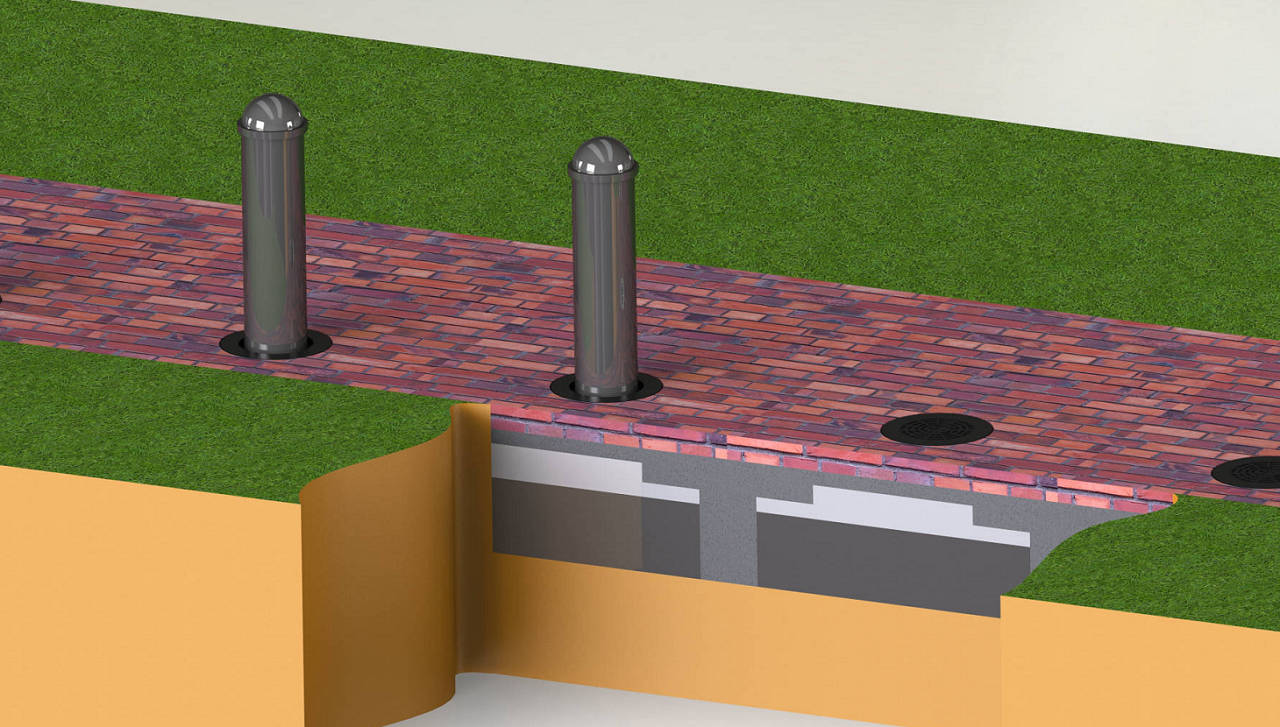

- Low foundation depth allows installation in urban areas with existing supply lines

- In order to avoid disturbance of the cityscape, the system allows an adjustment to the environment

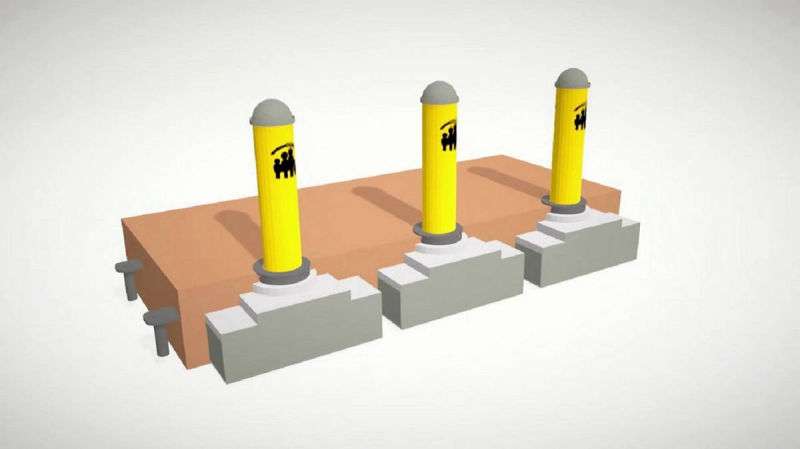

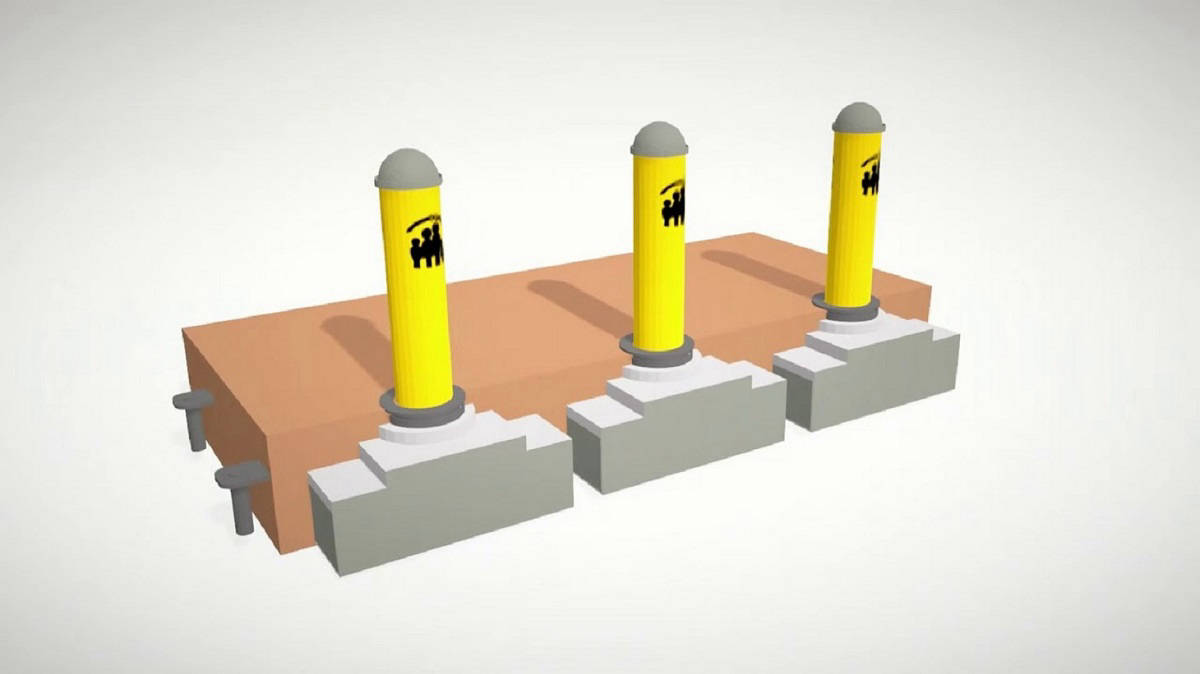

- Modular, connected structure of bollards with variable clear distance. In standard a clear distance of 1.20 m is provided

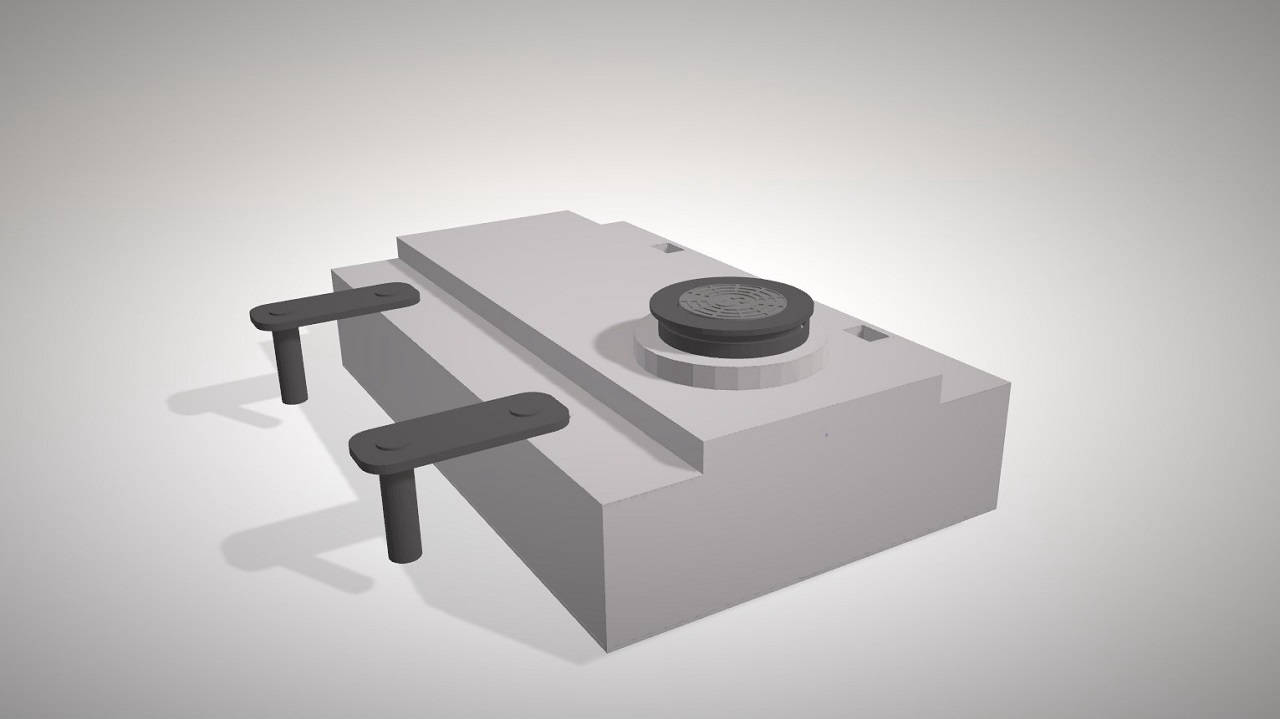

- The base elements are embedded in the ground and connected with each other by means of removable clamps

- By using clamps of different lengths, variable bollard distances can be realized. Also the non-linear laying of elements is possible. Concave radii from 12 m diameter on are realizable

- Steel bollards are inserted in a sleeve and can be removed if required. Exchange of the bollards between different base elements enables a protection different locations with the same equipment

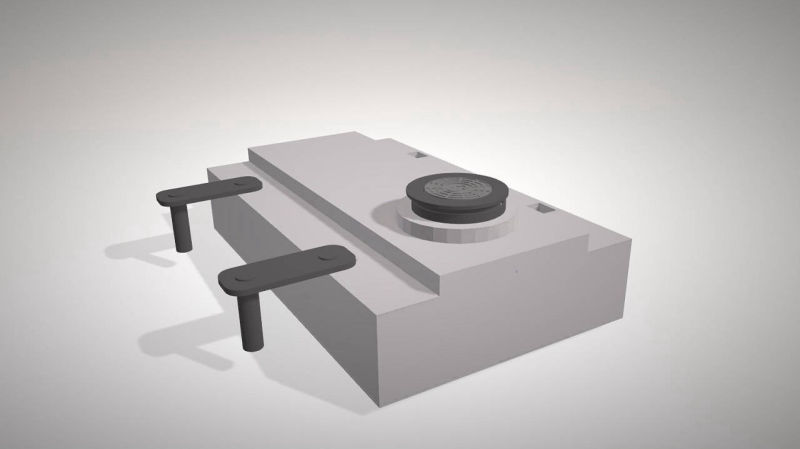

- If the steel bollard is removed from the sleeve, it is covered with a street cap. The road cap is approved for regular road traffic (class D400), so that the system is also suitable for roadblocks

- The structure is loose. No formwork or concrete casting work is required for installation

- The use of prefabricated concrete elements reduces the required construction time and largely avoids the impairment of the environment

- The bollard protection system is delivered completely assembled, becomes installed in the prepared Building pit and connected with each other by means of the clamps. Remaining trenches are backfilled and the surface applied

- Industrial production greatly avoids the occurrence of installation errors

- The base elements can be removed non-destructively via cast-in waved anchors and can be reused. This means that construction work under the bollard protection system (such as work on supply lines or sewerage) is easyly possible

- Removable steel bollards in a coverable steel sleeve allow the temporary Passage outside of secured times

- A foundation depth of 60 cm enables the installation of the elements in Urban areas with existing supply lines. In case of straight-line installation, between the base elements a distance of 25 cm remains

- Adjustable bollard caps and removable bollards allow the harmonious fitting of the bollard systems into the cityscape

- The stepped surface allows the integration of the bollard system into the environment. A surface covering of up to 15 cm height can be applied to the base element. The surface can be gravel, paving, but also an asphalt pavement is possible

- The street caps are approved for normal road traffic. They have a variable height (15 ±2 cm), so that they integrate seamlessly into the road surface

- Inside the base element a lattice-like steel substructure is cast-in for the absorption of the highest loads

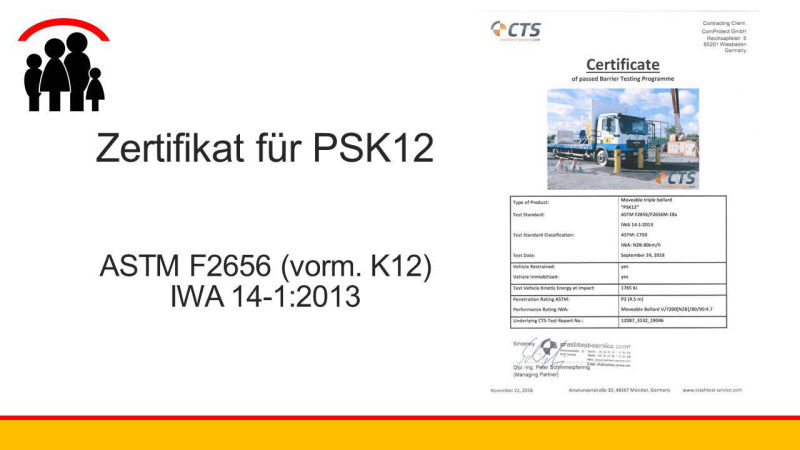

- The system is certified according to ASTM F2656/F2656M-18 (formerly K12) and IWA14-1 for a system consisting of at least three elements with a clear bollard distance of 1.2 m

- The strength was tested and proven by the independent auditing company CTS on 09/24/2018 in Münster

- Calculation and dimensioning was done in cooperation with Prof. Dr. Graubner, head of the institute of Solid Construction at the Technical University Darmstadt

- The construction is registered for a European patent

We use Coockies to provide you with the best possible service. You can find more information at Datenschutz. X